How JD Edwards’ Warehouse Management System Can Improve Your Supply Chain?

With the JD Edwards EnterpriseOne Warehouse module, your warehouse operations can be more efficient, inventory can be tracked and viewed better, and warehouse space can be optimized. In addition to being integral to manufacturing and distribution processes, JDE E1's Shop Floor Management and Inventory management tools enable it to manage inventory, space use and minimize labour resource.

In order to significantly improve your business processes and supply chain, Warehouse Management System (WMS) is among Oracle JD Edwards EnterpriseOne (JDE E1)'s key application modules. A lot of JDE customers are unaware of its advantages and capabilities. As part of this blog post, I'll highlight some of the key features and capabilities of this little-known module.

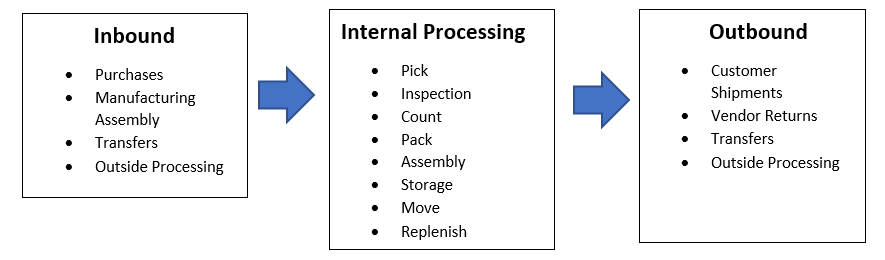

In the following flow chart, you can see the general steps involved in the Warehouse Management System Process:

Inbound:

Within WMS, inbound logistics refers to the handling of goods entering a facility. The receiving process for these goods often involves a Purchase Order as the goods are typically associated with purchases, also receipt is generated by many sources. These includes - Receipts for customer returns from an RMA issued by the Order System, the transfer of goods and services between warehouses within the corporation and the receipt of material on a Manufacturing Work Order that had been sent for processing by an outside organization. Once receipt received from various sources, material goes into inspection and then put away into the appropriate storage location.

Internal Processing:

Internal processing of WMS is all about handling of inventory. Mainly covers accuracy come from physical inventory count or cycle counts; intra-warehouse transfers; replenishment activities; picking - for customer orders, internal manufacturing, transfers, etc. and maybe packing as well. Warehouses are no longer merely for storage, and these added values and deferral activities are a crucial element of any warehousing job.

Outbound:

This process is exact opposite of receiving process and has a comparable set of transaction sources. Mainly Outbound shipments are corresponding with customer orders. However, the alternative sources are the inverse of the Receiving sources like Vendor Return connected with Purchase Orders, Transfer related with Inter warehouse movements inside the corporation and work order shipments to outside processors

From above description, any warehouse management system needs support not only from different processes but also from variety of transaction sources.

Below are few of the benefits that can be seen after the implementation of warehouse management system:

- Efficient material flow

- Pre-defined movement processes

- Effective space utilization

- Automatic restoration of stock

- Lot serial number creation and tracking

- End to end integration of processes like Purchasing, Inventory, Manufacturing, Sales and Transportation

A warehouse management system allows organizations to maximize capacity while emptying partially occupied locations as soon as possible. Furthermore, this system can minimize the number of trips through the warehouse that employees make, thereby increasing productivity. Let’s discuss some of the Cyret offering and expertise in WMS space.

- Optimization of the pick, put-away, and replenishment processes

- Cyret helps clients set up zones for different types of storage such as bulk, high rack, flow pick, and return

- Our solution integrates with barcodes and wireless radio frequency data collection devices so that goods can be tracked accurately and efficiently through the process.

- Generate a material movement plan for a facility, product, and customer by establishing multiple rules (minimums, maximums, substitutions, promises) and dates (lot, serial, expiration, shelf)

- Our cross-docking logic helps to maximize product flow by allowing orders to be pegged to planned receipts

- Offers dual units of measurement (catch-weight) with user-defined error tolerance

- Using license plating technology, the solution simplifies orders and inventory transactions and improves fulfilment accuracy

Cyret is an Oracle trusted partner having extensive expertise in warehousing space. We helped fortune clients and provided them integration of JD Edwards WMS module and barcoding solution. Contact us today for a free demo and discovery workshop.