Supply Chain Management

What Is SCM – Supply Chain Management?

Supply chain management is the management of the flow of goods and services and includes all processes that transform raw materials into final products. It involves the active streamlining of a business's supply-side activities to maximize customer value and gain a competitive advantage in the marketplace.

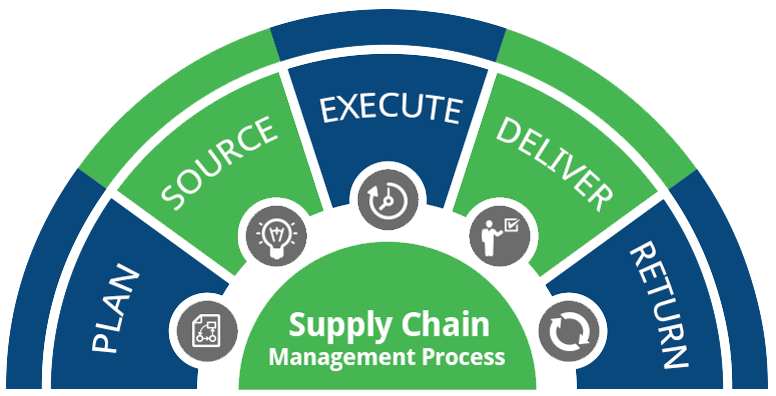

Different Stages In Supply Chain Management

Planning

Planning is imperative to control inventory & manufacturing processes. Companies should have a way to effortlessly match supply with aggregate demand by developing a course of action using analytics. Smart companies have a vigilant eye on the demand variations along the value chain to avoid Bullwhip effect for this they use ERP systems which efficiently stores all information which can be reviewed on demand for analysis to identify variations and create effective pathways.

Sourcing

Sourcing is identifying vendors who will procure goods & services to meet planned / actual demand in most economical and efficient way. Sourcing can be of perishable as well as non-perishable products. For perishable products it is mandated to have a minimum supplier's lead time which will support a minimal inventory approach. For non-perishable products, the supplier's quoted lead time must be watched upon to avoid the inventory reaching to zero to avoid revenue losses.

Execute / Manufacture

Sourcing is identifying vendors who will procure goods & services to meet planned / actual demand in most economical and efficient way. To derive the required outcome, the company will perform all activities to transform the raw material to final product.

Activities such as assembling, testing and packaging are covered here.

Deliver / Logistics

Finished goods as planned must meet the customer's expectations through the company's delivery channels and logistics services.

To have seamless delivery, the company uses various freights namely, road, air and railways.

Any delay or lapse in the logistics impacts the brand and image of the company in the market.

Manage Returns

Managing the returns is a post-delivery customer support process that is associated with all kinds of returned products. This is also known as Reverse Logistics".

It is a very important aspect within the supply chain management to minimize potential deterioration of relations with customers.

On the flip side, the company returns the low quality, defective, expired or excessive raw materials to the suppliers.

Why Is Supply Chain Management Important?

.png)

Controlling manufacturing processes can improve product quality, reducing the risk of recalls

.png)

Shipment controls that minimize customer service costs by preventing excessive inventories and shortages

Supply chain management provides several opportunities for companies to improve on profit margins.

Why Do I Chose Supply Chain Management With Cyret?

CYRET has built its intellectual capital based on a decades-long experience in implementing and supporting various ERP based solutions that allow our customers to assess supply chain aspects on the fly.

It has implemented many ERP's successfully, allowing the customer to choose the most useful one with just the modules he or she needs.

Over the years, Cyret has built its reputation as an ERP provider who can help you produce results while on the move by leveraging the mobility options.

Many notable achievements which include bar code integration for inventory management for client to enable real-time assessments of available items in stock.

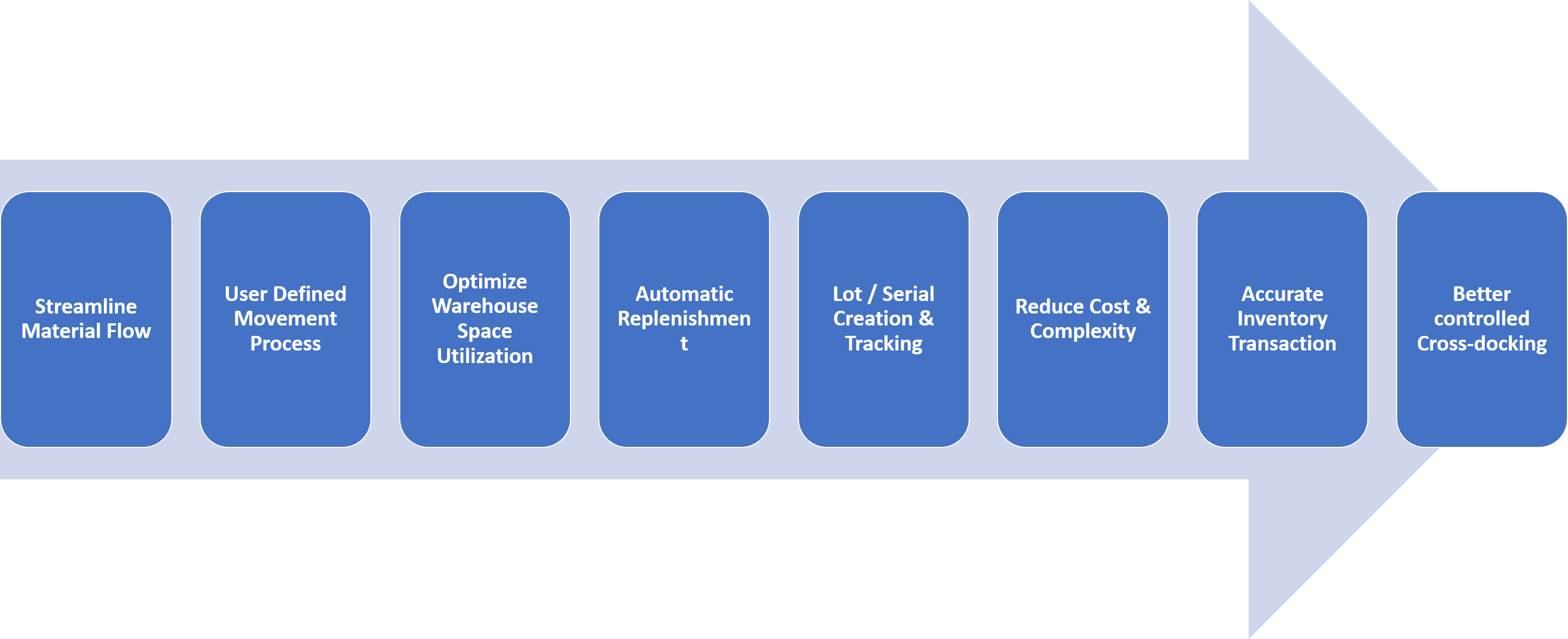

Benefits Of Choosing Supply Chain Management

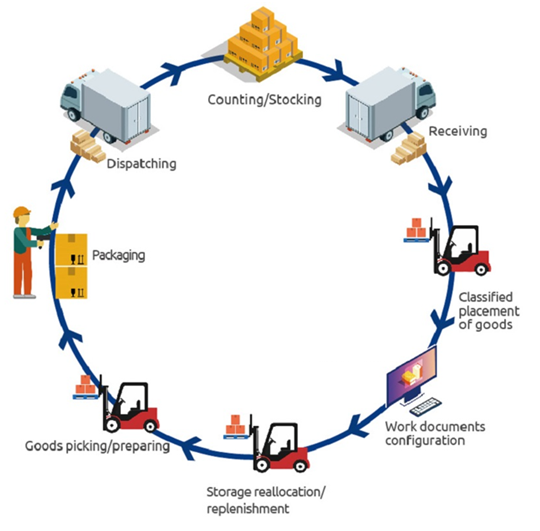

Cyret Offerings & Expertise Solution For Barcode Integration

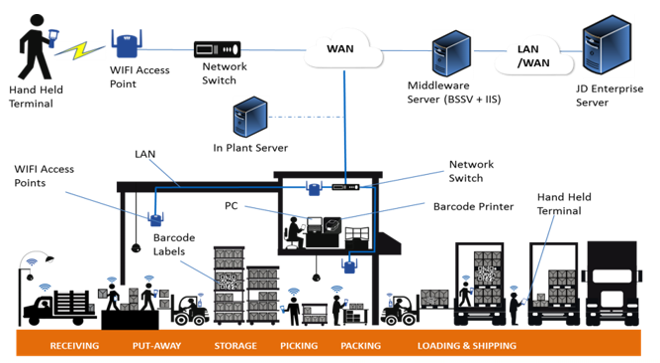

Cyret Solution

- Provide WMS & Barcoding solutions with features like wireless scanning, wireless data entry solution to take care of material movement activities at

- Bottling units

- Bonded Warehouses

- Implement solution at 5 locations covering as a pilot

- Provide custom fit Barcode frontend solution

- Integrate all Stock Movement operations with barcode solution

- Current ERP (JD Edwards 9.0)

- Warehouse Management

Value Delivered

- Seamless integration of JD Edwards WMS module with Bar Coding solution

- Easy to handle HHT solution for less experienced user

- Increased efficiency and time saving due to reduced manual work

- Optimized storage space design and inventory control

- Improvement in Operational Efficiency in Raw Materials and Finished Goods handling